This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

explore modular spine houses

Modular prefabricated houses are a modern solution guaranteeing short construction time and low cost of running.

We have been manufacturing precast concrete systems, sewage treatment and pre-treatment devices and decorative concrete elements for the past 20 years.

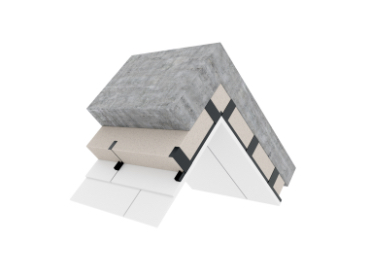

wall – section

roof – section

entresol – section

Installation

of a modular house

Preparation of house elements from prefabricated concrete takes place in the factory using modern technologies and machinery. The installation itself takes no more than a week.

the base has an internal length of 640 cm and a width of 310 cm

high resistance to weather conditions

the possibility of obtaining any surface

prefabricated spine houses

The technology of prefabrication of modular houses is widely used in Europe. This solution enables quick building without the need to build foundations. It provides more durable solutions than traditional construction and low operating costs. SPINE are prefabricated houses with unconventional design.

Modular house components made of concrete are prepared in the factory under special conditions and under the guidance of experienced specialists. Elements are prepared very precisely, with a great emphasis on details. On your plot already in three months.

See photos of the modular house

frequently asked questions

- Why is it worth investing in a modular house?

- What is the price of a prefabricated house?

- How long does it take to build a prefabricated house?

- Is the building passive/energy efficient?

- How to insulate and heat concrete houses?

- Does a modular home require foundations?

- How about the interior/room layout?

- Is the prefabricated house durable?

answer

As a company, we focus primarily on quality, the same applies to a prefabricated SPINE houses.

Another important reason to choose our product is the speed of workmanship – you can get the keys to your fully finished modular house in less than three months!

Design – an unconventional line allowed to create an innovative project based on traditional solutions. The form of our prefabricated house allows you to trap a piece of Scandinavia in the space of your own garden.

The cost of building a prefabricated house does not exceed the price of buildings constructed in conventional technologies. However, an additional, important factor should be taken into account – time. It turns out that the price becomes much lower than the prices of houses built in a traditional way.

The construction of prefabricated houses in SPINE technology, can not be determined otherwise than instant. The closed state together with insulation with closed-cell foam is built in no more than a week.

The concept of a passive building is a multidimensional term, the product of the technologies used in the building. Our solution fits perfectly with the ideas of buildings that minimize energy consumption, starting from the way of warming, through recuperation, way of heating, ending with photovoltaics. The SPINE modular house is to be an ecological house.

Our house made of concrete is insulated internally with closed-chamber foam sprayed by machine on structural walls. This solution allows you to get a positive thermos effect, with minimal energy loss.

The heating technologies depend on the customer’s preferences. For its part, BEWA offers solutions such as recuperation, which allow you to optimize heating processes.

Nothing could be further from the truth! The use of u-shaped elements means that the body itself is a foundation. Only earthworks involving the replacement of a 40 to 60 cm thick soil layer are required.

Interior decoration, layout of the rooms, or even the division of the floors are a matter of individual arrangements. The BEWA prefabricated house technology offers a whole range of possibilities from a one-story house with a spacious high living room with kitchen, to a small two-story house with a comfortable arrangement of rooms.

It can’t be more durable! Reinforced concrete construction ensures the indestructibility of a prefabricated house. The constructed building will serve not one, but many generations of potential residents.